BACKGROUND

With an ever-increasing focus on resilience and reliability, Virgin Media embarked on a journey to upgrade their Baguley Data Centre to meet the Tier 3 standard set out by the Uptime Institute. The project plan was to integrate a new generator with the existing two generators on site whilst remaining operational and live. It was acknowledged from the start that this exercise would be challenging due to the limited space on site and the necessary integration that would have to take place with the existing generators. The criteria was not only to offer true value for money but to demonstrate a detailed understanding of the project requirements and associated risks. Having worked directly with Virgin Media on several multimillion-pound projects over the years, we were aware of what was required in working with VM on these types of projects. Over the course of the tender period, we demonstrated our knowledge and ability, which led to Shenton Group being awarded the contract to carry out the generator installation.

PROJECT OVERVIEW

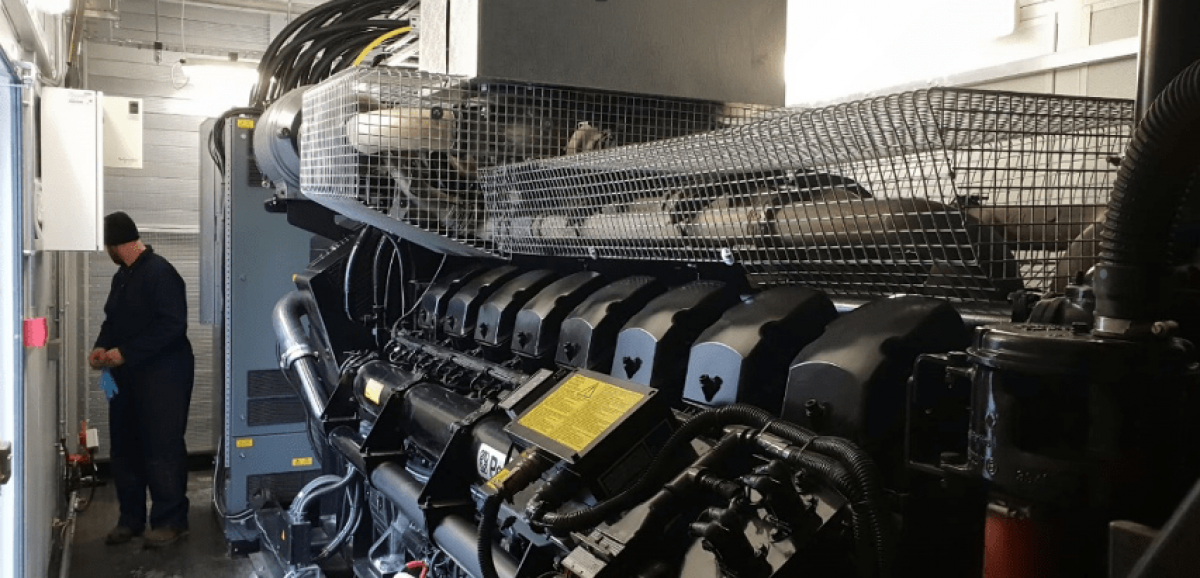

Once the detailed design had been completed and signed off, Shenton Group manufactured and supplied a 2200kVA generator using the combination of a Perkins Engine, Mecce Alte alternator and ComAp control system. This was housed within a bespoke ‘walk around’ acoustic container to ensure it did not exceed the maximum noise level of 82dB(A) @ 1 metre in free field conditions. As per the client’s specification, the inlet attenuator was fitted with a motorised inlet damper in a spring open/motor closed configuration, and the outlet attenuator was equipped with a gravity damper. The generator also required a bulk fuel tank capable of holding 30,000 litres of fuel and an extended exhaust stack to ensure all fumes were properly vented away from the building, for which Shenton Group carried out the complete installation. As well as the generator enclosure Shenton Group also supplied the switchgear enclosure, which was mounted on a steel gantry allowing the generator to be located directly below the switchgear enclosure. This reduced the overall footprint required and reduced the cable runs from the generator output to the relevant switchgear panels saving time and money.

The second part of the project and by far the most challenging was integrating the new generator with the existing 2 x 2200kVA generators and the two mains supplies that fed the site. This, along with the additional customer requirements, led to one of the most complex control systems we have ever seen within the industry, which was fully designed, programmed and commissioned in-house at Shenton Group. To enable this integration, we upgraded the site-wide control system on the two existing generators as well as the mains incoming ACB’s to a ComAp system and configured all three generators to not only synchronise with each other but also the two incoming mains supplies simultaneously. The system was set up in this way to ensure full redundancy as per Tier 3 and to allow for load sharing and a ‘no-break’ return to mains in the event of a power outage.

The final part of the project was to remove the existing 65,000-litre bulk fuel tank from the site and to replace it with 2 x 30,000-litre tanks so that the existing generators had the same capacity as the new generator, but by separating each system, we increased redundancy. Shenton Group looked after all elements of the fuel pipework, transfer system and civil works for this element of the project. As with any installation of this nature, our project manager oversaw all elements of the project, including the crane lift, G99 application process and testing, RAM’s, necessary site management plans and issuing the final manuals and drawings. The complete installation underwent final testing and commissioning to ensure that the technical requirements set out at the start of the project had been achieved.