Client: Dornan Engineering Services Limited

Sector: Mixed-Use

Location: London

Products/ Services

- Design

- 1870kVA generator

- 2200kVA generator

- Bespoke electrically driven radiators

- Bespoke acoustic attenuation

- 2 x 12000-litre bulk fuel tanks

- Bespoke synchronising ComAp controls package

- Delivery, off-loading and positioning

- Mechanical and electrical installation

- G99 application process and witness testing

- Commissioning

- Maintenance contract

Background

Marble Arch Place, located on the corner of Bayswater Road and Edgware Road in Marylebone, is a new mixed-use development consisting of an 18 storey residential tower with 54 apartments and a seven-storey commercial building providing over 95,000 sq ft of office space. This prestigious development, designed to the highest quality specification, is a new landmark building for London.

Dornan was the appointed mechanical and electrical contractor on the project, and having worked with them in the past; they reached out to us to support them with the life safety and backup power solution for the development.

Project Overview

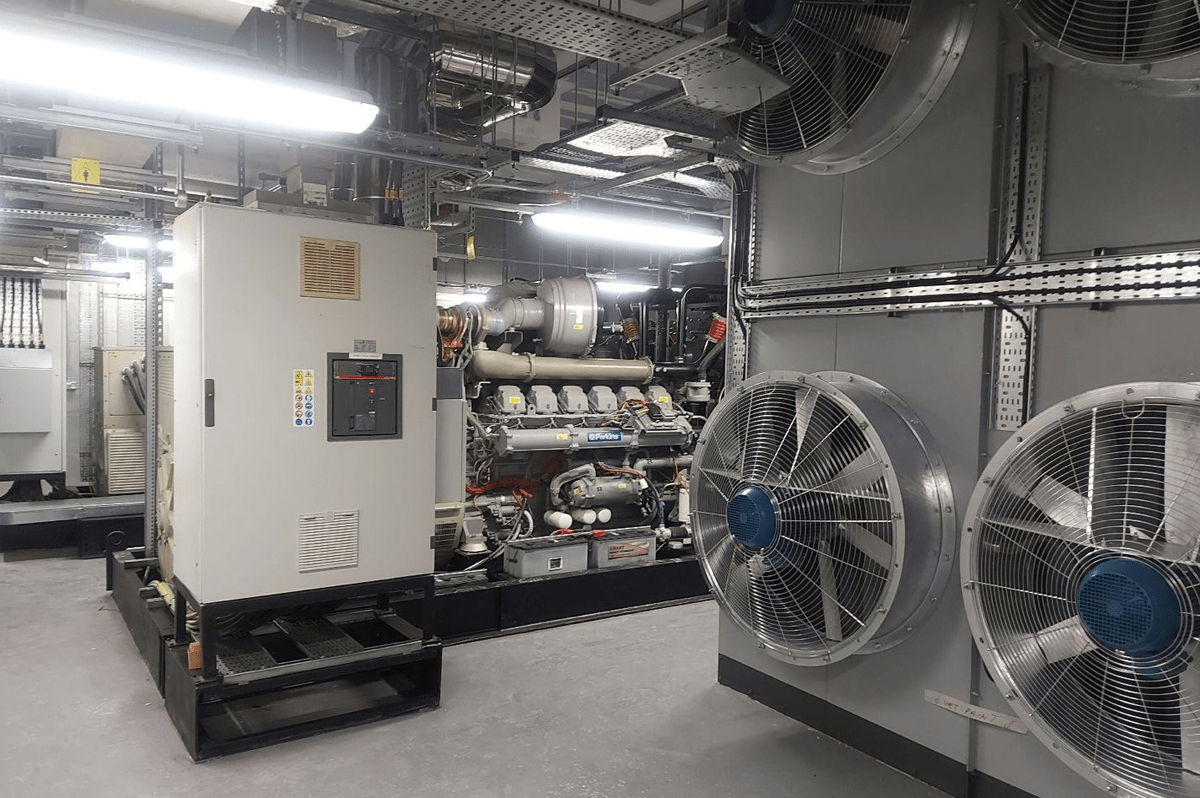

Working to the consultant’s specification, we supported Dornan heavily in the final detailed design stages to produce a cost-effective solution that achieved all of the client’s deliverables. The solution consisted of 2 LV generators, a 1870kVA and a 2200kVA; both built with bespoke electrically driven radiators to achieve the required variable volume air-flow with generator temperature. The units were installed in a single plant room with a bespoke acoustic and forced air ventilation system designed to achieve a noise rating of 50dB@1. The generator day tanks were connected to two 12000 litre bulk fuel tanks with Lloyds registered double-skinned pipework, and a complex PLC control system controlled the transfer pumps.

As the power solution was to be located in the basement, the generators needed to be dismantled into component parts to enable them to be skated into position before being rebuilt. Shenton Group looked after all elements of these works, including the full lift and shift package followed by a complete mechanical installation.

The system needed to allow for seven different scenarios, including synchronising the generators with each other, two separate mains supplies and a 70kW CHP. Our in-house design team custom-designed and programmed the ComAp controls package to allow for this, utilising ComAp Intelisys controllers on the generators and ComAp Intelimains controllers in the switchboards, integrating with the sitewide PLC system to provide seamless and safe interlock and control of the mains intake breakers and panel bus couplers. The system also incorporated Loss of Mains protection and parallel limit run timers to comply with the latest G99 regulations.

Outcome

The development is now fully supported by a reliable backup power solution that covers all potential site scenarios.

“The complexity of the project and the problem-solving was enjoyable. I am proud to have worked on such a prestigious project in the heart of London.”

Daniel Skudder – Shenton Group Project Manager