Client: FP Hurley

Sector: Councils & Government

Location: Bristol

Products /Services:

- Design

- 530kWe CHP

- Bespoke attenuation

- Bespoke ventilation system

- Delivery, off-loading, rebuild and positioning

- Mechanical and electrical installation

- G99 application process and witness testing

- Commissioning

- Maintenance contract

Background

In recent years the Bristol City Council has been putting a lot of investment into the city’s development. In reviewing the city’s environmental impact and with the aim of reducing carbon emissions, the council entered into a district heating scheme utilising a CHP unit. In short, a district heating scheme is a way of distributing heat generated in a centralised location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. In this instance, the CHP provides hot water and electricity to many buildings, removing the need for each building to generate this energy individually.

When FP Hurley (Mechanical & Electrical Contractor) secured the project, they had concerns about the specified CHP size. They engaged with Shenton Group over several meetings to redesign the solution in conjunction with the project consultant. Shenton Group were then chosen to provide the CHP system after providing extensive technical expertise and value in finalising the solution.

This is not the first time that Shenton Group have been chosen to support the Bristol City Council due to technical ability. In 2016 we designed, supplied, installed and commissioned a standby generator to provide backup power to the council offices in the event of a power cut. Due to space restrictions, this was also a challenging installation as it was installed in the same basement as the CHP.

Project Overview

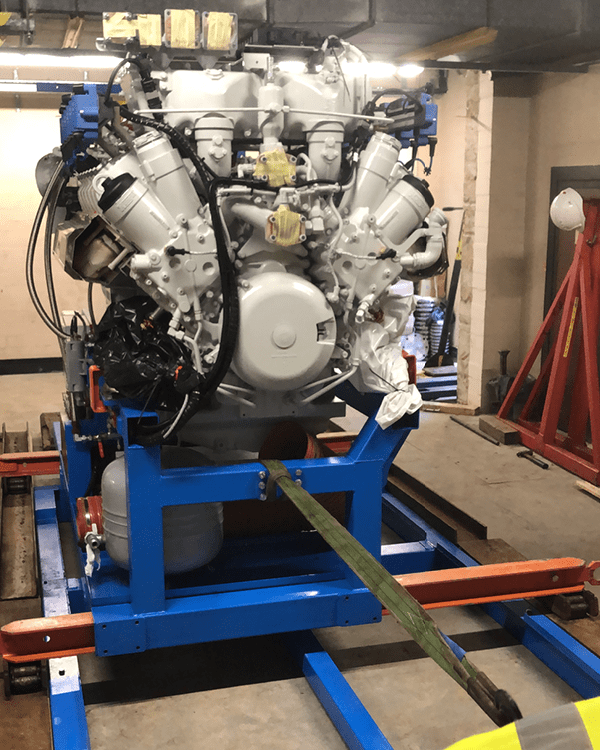

To overcome the space restrictions, the CHP had to be dismantled and delivered to the site in individual components. The parts were carefully craned down through a gap that at times, had extremely limited space – as little as 10 inches on each side. The CHP was then rebuilt in its final position by Shenton Group engineers. Due to spacial restrictions, we installed a bespoke ventilation system to ensure the CHP could run 24/7 without overheating. To reduce the number of times engineers would need to attend site and to reduce future maintenance costs, Shenton Group installed bulk oil tanks and designed a bespoke filling system. After the rebuild and installation was complete, the Shenton Group engineers led a successful commissioning phase, including G99 testing.

The solution comprised of a Tedom M530 (530kWe) CHP solution complete with bespoke attenuation and ventilation system, full breakdown and rebuild, lift and shift, commissioning, and G99 certification.

Outcome

This solution provides the Bristol City Council network with huge electrical and heat savings and provides reductions in the city’s environmental impact. The CHP is also under a Shenton Group maintenance and monitoring contract to ensure optimal lifetime performance.

One of the main challenges with this project was to fit the CHP unit in an existing space with very limited access. I found the planning by Shenton to be excellent, which ensured that the delivery and installation of the unit went very smoothly despite the confined space.

Jody Lockyer, Construction Project Manager Energy (Heat Networks) Bristol City Council