Location: UK

Products/ Services

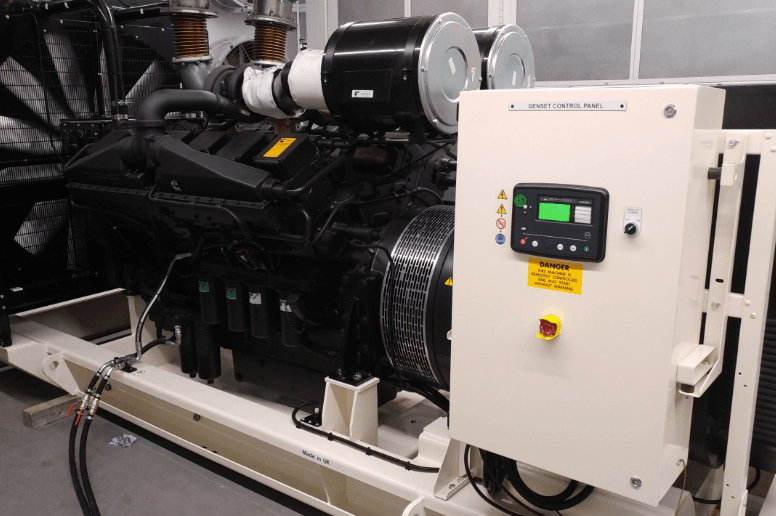

- 2 x 1100kVA standby rated diesel generators in an N+1 configuration

- Design and build

- Delivery, off-loading and positioning

- Bespoke 100 metre fuel transfer line

- System commissioning

- 22 maintenance contracts

BACKGROUND

A new baggage substation was being developed and required a generator solution with a fast turn around. The initial power solution was originally designed around another manufacturer’s equipment who unexpectedly pulled out of the project. This left the Airport in a difficult situation, needing to find a supplier who could work with the original design.

As with all airports, a reliable backup power supply is critical to ensure the facility can remain operational in a mains power outage.

PROJECT OVERVIEW

Within two weeks, we designed a workable solution giving our client confidence that we could deliver the project to the specification set out at the beginning of the project. Shenton Group supplied 2 x 1100kVA standby rated/1000kVA prime-rated generators utilising Cummins engines and bespoke radiators. This engine and radiator combination allowed us to cool air in the limited space available.

To reduce noise, both generators were then installed on anti-vibration mounts within a plant room. Shenton Group supplied and installed a single inlet attenuator and 2 x outlet attenuators to ensure that the noise level did not exceed 75 dB(A) @ 1 meter. These were fitted with vermin guards, fixed weather louvres and also motorised fire dampeners on the inlet attenuator.

Each generator had its own 2000 litre day tank connected to the generators in a flow and return configuration and fitted with a drop-weight fire valve for further protection. These day tanks were then connected to the existing bulk fuel tank on-site by installing 100 metres of BRUGG pipework, creating a new fuel transfer system to enable increased run time. Both generators were synchronised to 2 transformers using Deep Sea Electronics controllers to provide additional power resilience.

Shenton Group also looked after the on-site cranage, exhaust flues, electrical and mechanical installation, as well as carrying out the Factory Acceptance Testing, commissioning, and Site Acceptance Testing.

OUTCOME

The end result was a true turnkey project that met the original criteria set out in the specification delivered by Shenton Group.

Due to the nature of the site, a lot of the works had to be completed outside of normal working hours to keep operational disruption to a minimum whilst meeting the stringent security measures on-site.

James Norman – Shenton Group Generator & UPS Project Manager:

The client was impressed with the generator solution. Due to our work on this project, we now hold maintenance agreements for all 22 of the airport’s generators within our service team.